Boost Your Tools: Discover Costs Komatsu Undercarriage Parts Solutions

Boost Your Tools: Discover Costs Komatsu Undercarriage Parts Solutions

Blog Article

Increase Productivity With Undercarriage Parts and Its Makes Use Of

Understanding the detailed elements that compose the undercarriage of heavy equipment is crucial for business intending to optimize their operational efficiency. From track shoes to idlers and gears, undercarriage parts play an essential function in the efficiency and long life of equipment. The calculated use of these components can result in substantial improvements in efficiency and cost savings. Let's discover just how services can harness the power of undercarriage components to enhance their operations and drive success in an affordable market.

Significance of Undercarriage Parts

Routine upkeep and timely substitute of undercarriage parts are critical to avoid pricey downtime and maximize productivity. Damaged undercarriage parts can result in minimized traction, raised fuel usage, and accelerated wear on other components of the equipment. By buying premium undercarriage parts and sticking to a strict maintenance routine, operators can maximize the efficiency of their heavy machinery and extend its service life.

Common Kinds Of Undercarriage Components

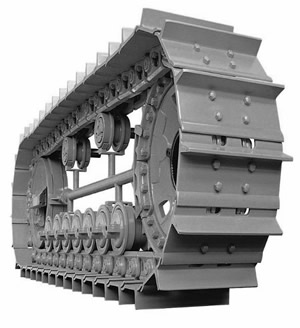

Essential elements crucial for the reliable procedure of heavy equipment, undercarriage parts play an essential duty in making certain ideal efficiency and durability of the tools. Some usual types of undercarriage parts consist of track chains, track shoes, rollers, idlers, gears, and track structures. Comprehending the feature and significance of these usual undercarriage components is essential for keeping hefty machinery in optimum functioning problem, minimizing downtime, and optimizing efficiency on work sites.

Advantages of Regular Maintenance

Enhancing operational effectiveness and lengthening tools lifespan, routine upkeep of undercarriage parts is critical for making best use of hefty machinery efficiency. By sticking to an organized upkeep timetable, operators can protect against costly break downs and lessen downtime. Normal inspections and maintenance of undercarriage elements such as tracks, sprockets, rollers, and idlers not just make sure smooth operation however likewise add to total security on job websites.

Enhancing Equipment Efficiency

In addition, choosing the appropriate undercarriage parts for particular operating problems is crucial. Elements such as the kind of surface, workload, and ecological problems need Our site to be considered when choosing undercarriage components. Utilizing high-quality components that are designed to withstand the needs of the task can improve total tools efficiency and longevity.

In addition, maintaining undercarriage parts well-lubricated and clean is important for smooth procedure. Dirt, particles, and absence of lubrication can cause early wear and tear on elements, bring about reduced efficiency and possible failures. Normal cleansing and lubrication regimens can assist avoid these problems and guarantee constant equipment efficiency.

Cost-efficient Solutions for Services

To maximize undercarriage components properly and make certain long-term devices efficiency, companies have to focus on affordable remedies that align click here for more with their operational needs and budget plan restraints (komatsu undercarriage parts). Investing in premium undercarriage components can lead to significant financial savings in the long run by minimizing downtime, upkeep prices, and the risk of unexpected equipment failings.

In addition, organizations can check out alternate undercarriage parts such as aftermarket components that fulfill market requirements and specifications at a lower price than OEM components. By thoroughly assessing their options and partnering with trusted distributors, organizations can efficiently manage their undercarriage component costs without compromising on performance or integrity.

Final Thought

In final thought, undercarriage parts play a vital duty in enhancing devices efficiency and efficiency. It is clear that undercarriage parts are vital parts for companies looking to improve performance and keep their equipment in ideal condition.

From track footwear to idlers and gears, undercarriage parts play a crucial duty in the performance and longevity of devices.The relevance of undercarriage parts in heavy equipment can not be overemphasized, as they are essential components that considerably influence the overall performance and durability of the devices.Crucial parts necessary for the effective procedure of hefty machinery, undercarriage components play an important function in article making certain optimum efficiency and longevity of the equipment.Enhancing operational efficiency and prolonging equipment lifespan, normal upkeep of undercarriage components is pivotal for making best use of hefty equipment efficiency. Furthermore, services can discover different undercarriage parts such as aftermarket parts that satisfy market requirements and specs at a lower cost than OEM components.

Report this page